Allegro MicroSystems has introduced the ACS37200, a galvanically isolated current sensor designed to increase efficiency and power density in high-current applications, including hybrid and EVs. Allegro says the ACS37200 addresses a key challenge facing EV and industrial power engineers: the heat and energy loss caused by traditional shunt resistors in high-current designs.

The ACS37200 features a conductor resistance of 50 microohms, which, according to Allegro, reduces power loss by 90 percent when compared to a conventional 0.5 milliohm shunt resistor in a 100 amp system. For example, a traditional shunt could waste up to 5 watts as heat, while the ACS37200 would limit this loss to 0.5 watts. This minimizes wasted energy and reduces the need for bulky heatsinks, enabling more compact and energy-efficient power electronics in EVs and related applications.

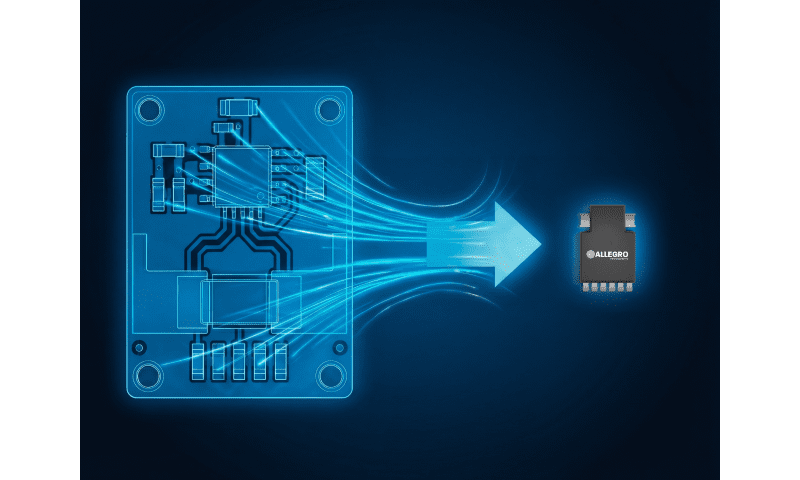

The sensor is packaged in a 100-square-millimeter PSOF footprint, which Allegro says is 70 percent smaller than its previous-generation ACS772 CB package and occupies 95 percent less board space than discrete shunt-based solutions. The small size and reduced thermal output allow designers to optimize system layouts for higher power density and reliability.

For EV traction inverters, battery management and other high-voltage power systems, the ACS37200 integrates certified galvanic isolation at 1,000 volts RMS (1,414 volts DC) within a single surface-mount package. It meets the UL 62368-1 safety standard and comes factory-calibrated, effectively replacing shunt resistors, isolation amplifiers, and associated passive components. This integration simplifies bills of materials, streamlines supply chains and reduces the complexity of high-voltage isolation design.

“Our customers consistently tell us that power is a major bottleneck. Systems need to monitor, convert and deliver more power than ever before in the same or even smaller form factors,” said Matt Hein, Business Line Director of Current Sensors at Allegro MicroSystems. “By drastically cutting power loss and offering a 95% reduction in footprint, we are giving our customers more design freedom, higher power density, and a faster path to building smaller, more efficient systems for the future of e-Mobility, industrial automation, and clean energy.”

Source: Allegro MicroSystems