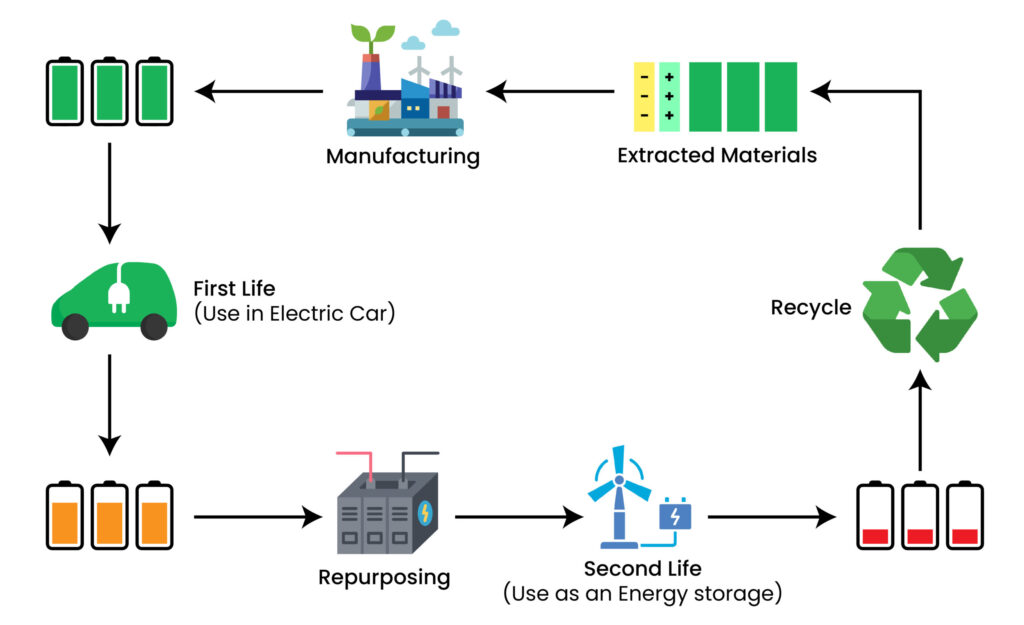

In today’s shift toward sustainable transportation, electric vehicle (EV) batteries stand at the forefront of green innovation. However, the journey from raw materials to recycled batteries is complex, involving significant environmental impacts, especially during extraction and manufacturing. Here’s a look at the full battery lifecycle, highlighting our commitment to a cleaner, circular economy for EV batteries.

1. Sustainable Raw Material Sourcing

A large portion of EV battery emissions, roughly 50%, occurs during raw material extraction and processing, particularly with lithium and nickel. By securing sustainably sourced materials, emissions per battery cell can be reduced by as much as 30% through methods like electrified mining and renewable energy usage during extraction. With global lithium demand for EV batteries expected to jump from 60% today to over 95% by 2030, sustainable sourcing becomes essential to balance both supply and environmental goals.

2. Cleaner Manufacturing and Reduced Emissions

Our approach prioritizes renewable energy at every stage. Cell manufacturing, which uses energy-intensive processes like electrode drying, can see significant emission reductions with 24/7 clean power and innovations like dry coating. Each step in the battery-making process has the potential for improvement:

– Material Choice: Opting for lithium iron phosphate (LFP) batteries lowers emissions by around 15-25% compared to traditional NMC batteries.

– Energy Consumption: Switching to fully electric processes and clean energy during manufacturing can reduce emissions by approximately 25% across the supply chain.

3. Recycling for Circularity

Recycling is a linchpin for long-term sustainability in EV batteries. End-of-life battery recycling can cut carbon footprints by up to four times compared to sourcing raw materials. As production volumes grow, recycling scrap material from battery manufacturing will further support sustainability. Efficient recycling systems are key to ensuring a stable supply of critical materials like lithium and nickel.

4. Transport and Logistics Efficiency

Although logistics contribute a smaller share to the overall emissions footprint (around 5%), innovations in low-emission transport methods, like rail, and localized battery supply chains in regions like the EU and the U.S. are helping drive decarbonization.

Key Lifecycle Facts

– Emission Reduction Potential: Up to 30% reduction per cell with sustainable raw material sourcing.

– Recycled Content: Batteries with a higher share of recycled materials have about four times less impact on emissions.

– Future Demand: With 95% of lithium expected to be allocated to battery production by 2030, sustainable sourcing and recycling are more crucial than ever.

With continuous investment and innovation, we’re paving the way for a future where EV batteries support a sustainable, circular economy from raw material to recycling. As demand accelerates, our commitment remains: delivering green, efficient, and responsible battery solutions for a cleaner tomorrow.

By focusing on sustainable battery life-cycle management, we’re helping to create a true “green premium” in the EV market and reducing global dependency on carbon-intensive mining practices.