We EV veterans remember the old days, when a battery pack was designed according to a strict hierarchy: cell, module, pack. Then, way back in 2019, CATL introduced a cell-to-pack architecture, which, by dispensing with modules, allowed a battery pack to be made lighter and smaller. This technology has since reached its third generation, and we don’t hear much about modules anymore.

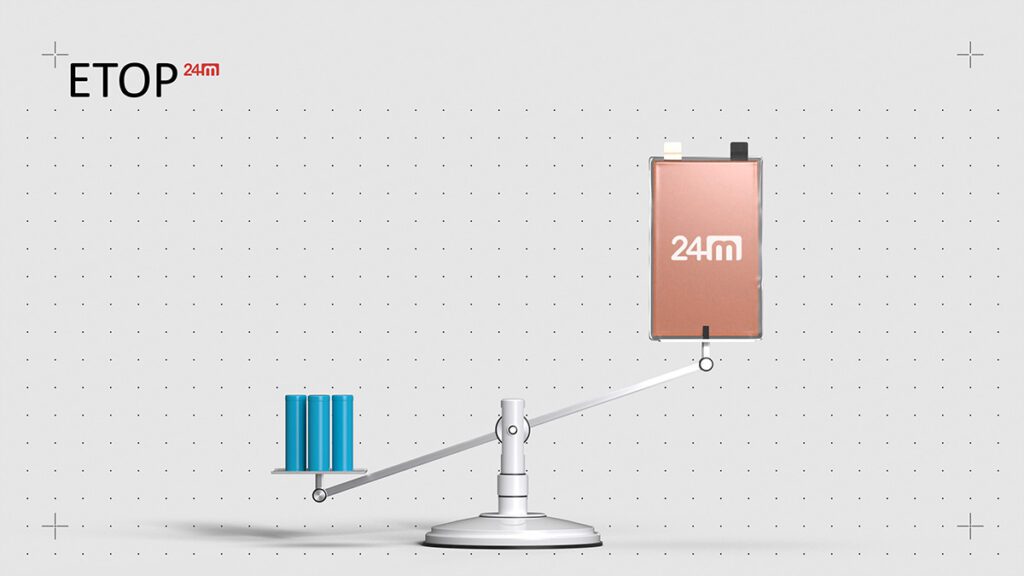

Now, EV battery manufacturer 24M Technologies has taken the next logical step, apparently dispensing with cells. 24M’s Electrode-to-Pack (ETOP) technology “seals electrodes in thin polymer films that are then integrated directly into the pack to vastly improve packaging efficiencies.”

“Lithium-ion batteries feature a large proportion of inactive, non-energy-carrying materials—such as supporting metals and plastics—within a cell’s casing, adding cost and wasting space,” 24M explains. “The ETOP architecture replaces this approach by creating a sealed cathode/anode pair that eliminates the cell and module and unnecessary materials. This allows manufacturers to achieve the highest energy density for any chemistry (NMC, LFP, NCA, sodium-ion, LTO, LiS, etc) at the pack level, because a higher percentage of the battery is electrodes, the energy-storing components.”

24M claims that its ETOP tech makes it possible for electrodes to comprise 80% of a pack’s volume, compared to the 30% to 60% of traditional battery packs. EV designers can choose to take advantage of the additional energy density either to increase range by packing more energy into the same size pack, or to reduce vehicle costs by using less expensive chemistries to deliver the same range with a smaller pack.

For example, according to 24M, a 75 kWh NMC battery pack could be increased in capacity to over 100 kWh, increasing range by 33% with no increase in size. Or, designers could replace NMC chemistry with less expensive LFP technology, resulting in a less costly pack with the same range.

24M also describes manufacturing benefits: “Because electrodes are sealed individually, electrode safety tolerances do not have to be as tight as in a traditional battery, improving yield and safety while reducing investment costs by eliminating the need for traditional high-tolerance and precision equipment. Because the sealed electrodes can be flipped, they can be connected in series and parallel arrangements, enabling anything from a compact 48 V battery all the way up to a mixed series/parallel 400-800 V pack, giving battery designers further freedom.”

“24M ETOP makes it easier to build compact, flexible and safe high-voltage batteries, presenting a revolutionary opportunity for EV manufacturers—longer ranges with the same chemistry or the same range with lower cost, safer chemistries, both in the same space,” said Naoki Ota, President and CEO at 24M Technologies. “It truly is the closest version of an ideal battery—it is essentially all active material in a sophisticated wrapper.”

Source: 24M Technologies