South Korean battery materials firm POSCO Future M, a subsidiary of steelmaking giant POSCO, says it has completed the pilot development of cathode material portfolio for all EV classes.

The company has developed ultra-high-nickel cathode materials for premium EVs and high-voltage mid-nickel cathode materials for standard EVs.

The materials for batteries in premium EVs maximize driving range by increasing the nickel content to over 95%, thereby increasing energy density. POSCO Future M is developing these materials for markets such as the US and Europe, as well as in urban air mobility.

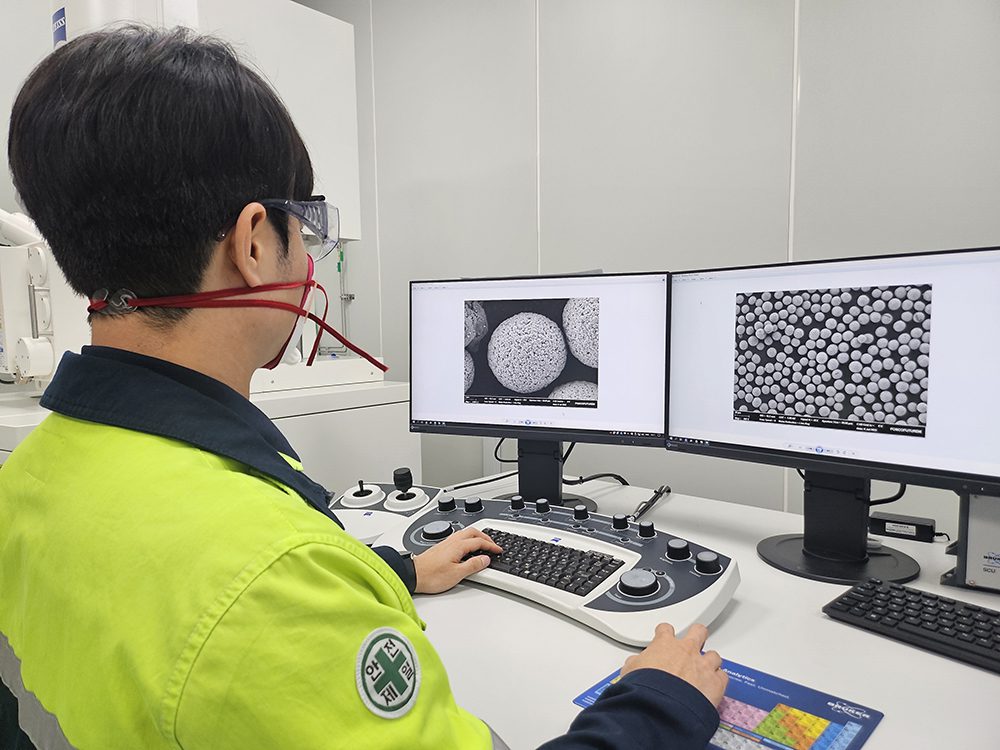

The ultra-high-nickel variant combines single-crystal materials, which combine key raw materials into a single particle structure, and polycrystalline materials. The rigid particle structure reduces cracking during charging and discharging. Adding other materials and coating the material surface further increases structural stability, according to POSCO. The company also says it has reduced costs by improving the productivity of the sintering process.

The mid-nickel version reduces the nickel content to around 60% while increasing the voltage to address the lower energy density. Increasing the manganese content and minimizing the shrinkage and expansion during charging and discharging through single crystallization enhance the material’s safety.

Using a non-porous precursor during manufacturing reduces the proportion of expensive nickel and cobalt in the raw materials and uses less expensive lithium carbonate as an alternative to lithium hydroxide.

POSCO currently produces and supplies premium cathode materials, primarily N8x. It expects mass production of the new materials to increase its competitiveness in the cathode materials market by addressing the needs of various automakers and battery manufacturers.

The company has also completed pilot development of lithium-manganese-rich (LMR) cathode materials and plans to secure mass production technology within the year. LMR cathode materials are attracting attention as a potential replacement for lithium iron phosphate (LFP) in the entry-level EV market, as they can use existing cathode production lines while offering superior recyclability, according to the company.

The company is also pursuing research and development of next-generation materials such as lithium sulfide, solid electrolytes and lithium metal anode materials at the POSCO Holdings Future Technology Research Institute.

Source: POSCO